Description

| Content | MW-LC500D | MW-LC1000D |

| Supply voltage | Single phase 220V+10%、50/60Hz AC(Customizable:110 V、50Hz AC) | |

| Power consumption | ≤4000 W | ≤8000W |

| Working environmenttemperature | 5℃~40℃ |

|

| Working environmenthumidity | 580% |

|

| Optical parameters | ||

| Average laser power | ≥500W | ≥1000W |

| Power instability |

|

|

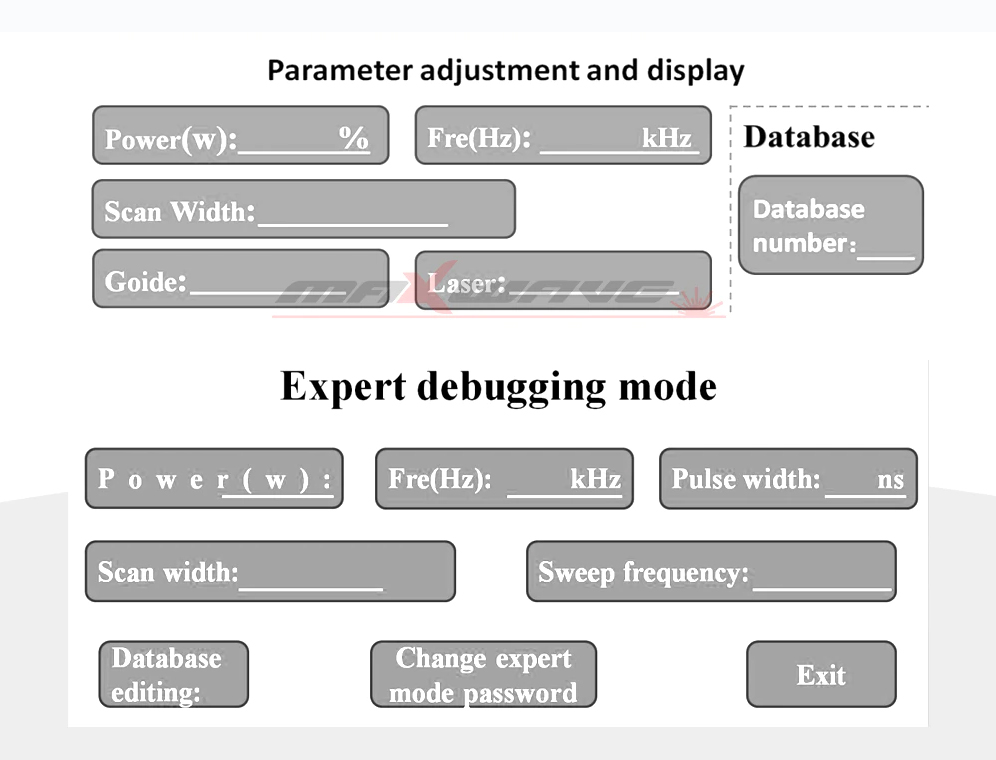

| Power regulation range(%) | 10-100( Gradient Adjustable) | 10-100( Gradient Adjustable) |

| Repeat frequency (kHz) | 10-50(Gradient Adjustable) | 10-50(Gradient Adjustable) |

| Fiber length | 15m | 15m |

| Cooling mode | Air cooling | Water cooling |

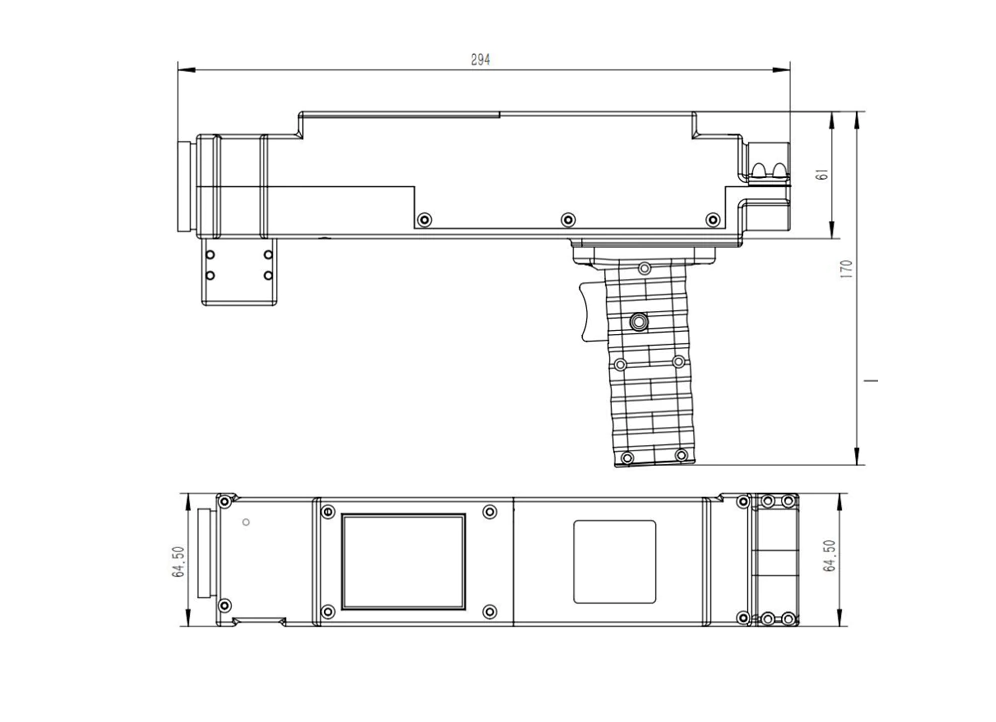

| Cleaning Head Parameters | ||

| Scan range(length * width) | Uniaxial:5 mm~120 mm, continuously adjustable;Biaxial: not less than 120 mm*60mm, length and widthindividually continuously adjustable; | |

| Scanning frequency | 10Hz-~300Hz Continuous Adjustable |

|

| Field mirror focal length | 160mm( Optional160mm-500mm) |

|

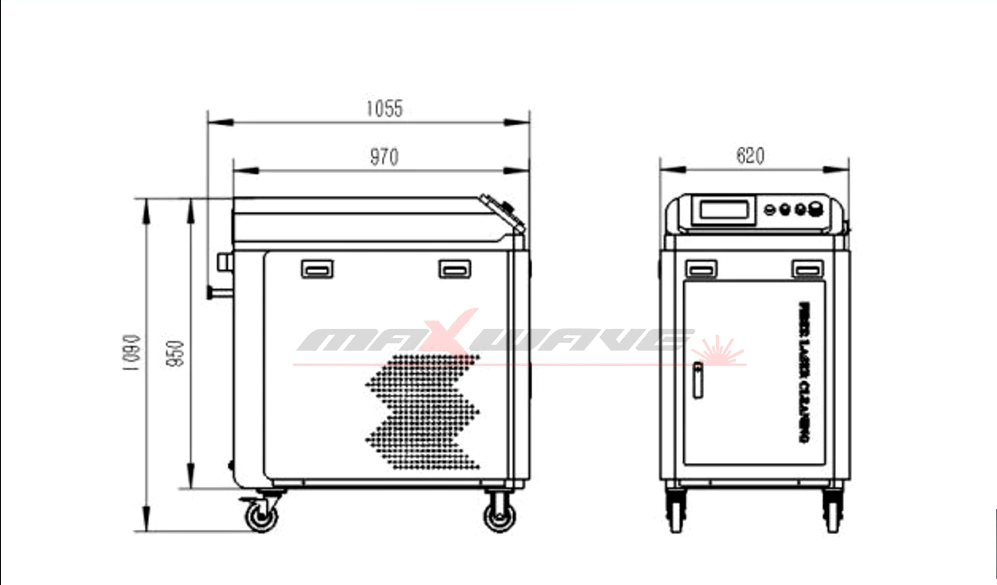

| Mechanical parameters | ||

| Machine size (excludingmoving wheels) | 1300mm×750mmx×1200mm | 1300mm×750mmx×1200mm |

| Machine Weight | About 240kg | About 280 kg |

| Cleaning head weight(including isolator) | About 1.9Kg | About 1.9 Kg |

| Mode of operation | Handheld/automated | Handheld/automated |

1.Powerful, short pulses, fast moving laser pulses act on the surface of the target, producing tiny plasma ruptures, shock waves, thermal stress, etc., causing surface materials to sublimate and evaporate.

2.The focused laser beam is capable of accurately evaporating surface objects or dirt.

3.Laser cleaning is suitable for metal surfaces. The treated and optimized laser beam does not alter metal properties or damage those laser treated surfaces. The precisely tuned laser beam acts only on the coating, residual residue or oxide, and does not harm the underlying parent metal surface.

4.By adjusting other parameters, the laser beam is able to achieve the desired cleaning effect accurately and easily.

1. Core technology. When we were a small factory, we have focused on the development of core components such as laser power supplies and optical path. Unlike other suppliers, they only sell through assembly equipment.

2. Independent research and development department. This means we can offer our customers customized machines and improve the equipment according to market changes

3. Dealer support plan. In the early stage of customers' market development, we provide technical parameters for the installation and use of equipment free of charge, share good marketing methods, help customers win the market and achieve success.

4. Strict testing. All of the suppliers we work with come from world-class manufacturers. Before the delivery, each machine needs to be tested and inspected for 48 hours (marking machine, welding machine) and 4-7 days (cutting machine) to ensure quality and safety.

5. Timely delivery. Each machine has an accurate assembly process and strict time control to ensure that customers receive goods in a timely manner.

6. After-sales service and guarantee. We offer a 2-year warranty and any problems occur during the period and we have a responsibility to resolve them. If any part of the machine is broken, we will repair it for free and send free accessories.